THE SOLUTION

Traditionally maintenance is not done on Corroded Contact Areas between pipe supports and pipelines due to the High Safety Risk resulting in Production Downtime and Cost. In order to gain access to the contact area, vertical displacement of the pipe or piping system from the pipe support is required.

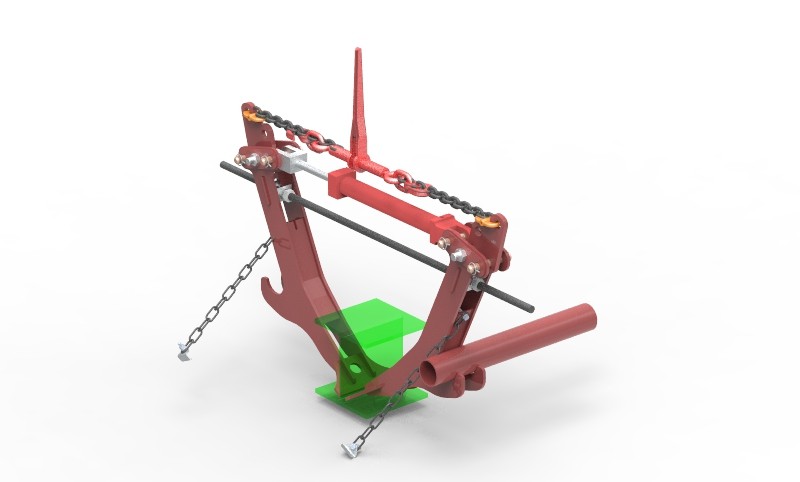

A SAFE Engineered Jacking System allowing access to Multiple Work Areas while the equipment is in Operation provides the solution. A combination of JAKU ARM JACKS, rated at a 6000 kg safe working load each, are utilised in achieving the required vertical displacement of selective or multiple product lines.

The patented* jacking equipment achieves a vertical lift of up to 80 mm, sufficient to perform all inspections (NDE, Visual) and maintenance / improvements. Initial lifting (break away) is done remotely to avoid any personnel exposure in case of a resulting leak in suspect contact areas. Mechanical lifting follows the initial breakaway. The piping system gets furthermore vertically secured by means of an engineered double lock-out system on the jacks thereby not creating a suspended load (working underneath is safe).

*SA Patented, USA & Foreign Patents applied for

IMPORTANT:

Lifting is done whilst the pipelines are in production and we always emphasise to our clients that this is dangerous if not dealt with professionally. It is important to understand that a Jacking Solution is provided, contrary to the selling or rental of jacks. This solution involves thorough upfront engineering (piping stress analyses) to determine a safe jacking procedure and jack positions. It further extents to Safety Procedures, Trained Personnel, Potential Deviation Analyses, Emergency and Safety Management and strict adherence to Client Safety Procedures.

JAKU ARM JACK SYSTEM: Lifting Simulation

KEY FEATURES OF THE JAKU ARM JACK SYSTEM:

- Engineered Device & used with an Engineered Procedure

- Safe Remote Vertical Lifting (Hydraulic)

- Lift while in Production

- Synchronised Lifting

- Lift Complete Pipe Rack / Multiple Lines Simultaneously

- Lift Selective Lines Only

- No Suspended Load

- Access to CUPS - Practically Anywhere

- Easy to Install and Operate by One Operation

Note: Specific jacking requirements can be engineered to suite your particular application.

IN DEPTH ENGINEERING AND JACKING STUDY (PER LINE) - STRESS PROFILE

.

ENGINEERING AND JACKING STUDY - POSITIONING OF JACKS

THE TOOL: 6000 kg JAKU ARM JACK POSITIONED ON PIPE RACK

SITE INSTALLATION, VERTICAL LIFT TO PROVIDE INSPECTION AND MAINTENANCE ACCESS